A Mumbai based entrepreneur has developed an innovative drive that interfaces between the prime mover and a host of driven equipment, individually or simultaneously.

Mr. Jaidip Shah is in the business of diesel powered applications like - generators, dewatering pumps, fire pumps, compressors, mixers, welding generators, etc. etc.

In the course of his business he found that very often a prime mover installed with one application is idle while another prime mover of equivalent capacity powers another application.

A classic example is the DG set and diesel powered fire pumpset application, where the fire fighting demand and the electrical power demand is rarely together. Similar is the case of a welding alternator & dewatering pump, at construction sites. There is definite scope in improving prime mover utility.

If the prime mover is to supply power to more than one application alternately or simultaneously, prime mover utility improves, resulting in obvious advantages such as cost, space, maintenance, spares - savings and increased reliability, etc. etc.

The list of applications that could be operated in tandem by a single prime mover is quite long. A device was needed that could do just this. And PLURODRIVE� was born.

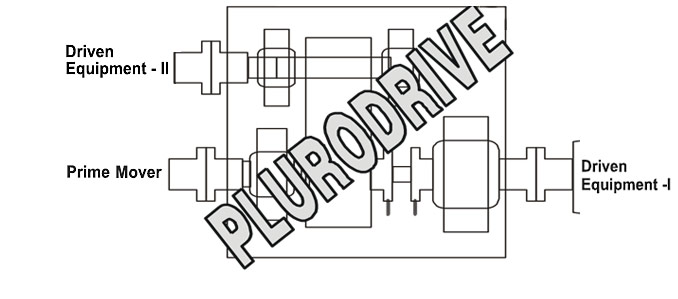

The PLURODRIVE� is a mechanical power transmission device, which transmits rotary power from prime mover(s) to more than one driven equipment, alternately or simultaneously, as required by a simple lever mechanism.

One end of the prime mover is connected to the input of this drive and various driven equipments such as welding alternator, pump, compressor, power alternator, cutter, conveyor, mixer, thresher, harvester, etc. are connected to the outputs provided.

Rotary power from the prime mover can now be transmitted alternately or simultaneously, as required through the PLURODRIVE�.

The PLURODRIVE� is made with the highest quality standard. All the inputs of this drive including technical expertise are the best available.

Initial market feedback indicates that in the years to come, the PLURODRIVE� will be used and accepted very widely. It will force engineers everywhere to think differently while designing or applying rotary power transmission solutions.

Reliance, Great Eastern Shipping, Parshwanath Petro-chem, Mittal Petro, Filler India Bottling, Bee-Am Chemicals, Mazgon Dock Ltd. , Mumbai Municipal Corporation, Ruby Mills, Aarti Industries Ltd., etc. etc.

Various features, advantages, applications, etc. of PLURODRIVE� are explained below.

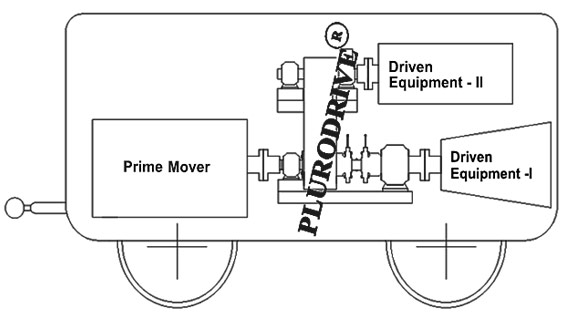

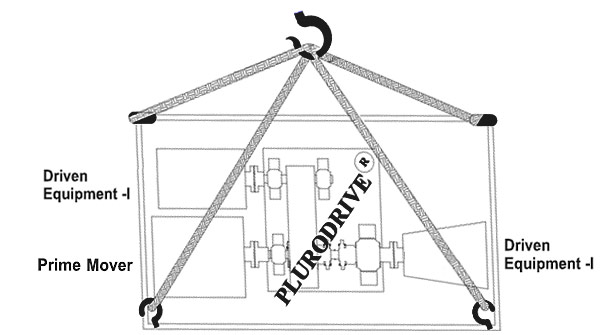

The assembly of prime mover, then the PLURODRIVE�, then the driven equipments are mounted on a common frame.

The arrangement now makes it possible for independent transmission of rotary power from the prime mover(s) alternately or simultaneously to two or more driven equipments. Thus getting two uses from the same prime mover resulting in many advantages as mentioned herein.

This is popularly used to run alternately or simultaneously two driven equipments like water pump and power alternator, power alternator and welding alternator, etc., by a single diesel engine. The single input multi output application is more used, however, variations like multi input single output, multi input multi output are also available.

FEATURES AND ADVANTAGES

- Lower capital cost: Obviously, reduction in capital cost because only one prime mover is required for two or more applications and lower space requirement.

- Lower fuel cost: There is no restriction on prime mover rpm vis-a-vis at least one driven equipment. So, prime mover is run at optimum speed and one gets better SFC.

- Prime movers and driven equipments of various different makes can be connected through the PLURODRIVE�.

- Lower maintenance and spares cost: Because one has to maintain only one prime mover in lieu of two, the maintenance and spares cost will come down.

- Design and manufacture: The PLURODRIVE� is designed and manufactured with the highest quality standard and in conformation with the latest design norms. PLURODRIVE� incorporates power transmission components of world renowned makes such as GATES*, CONTINENTAL*, etc. as required.

- More reliability: Since prime mover is used for two or more applications it is automatically maintained in good running condition and comes ON immediately when required in emergency.

- Regular maintenance drills not required: When the prime mover is used for only one application, it is made to run once or twice a month on maintenance drills, to keep it in good working condition. Such maintenance test drills are not required here because engine is also used for another application.

- Positive engagement: The PLURODRIVE� incorporates a unique positive engagement design. Whereby the units can not accidentally disengage while running.

The set can be built in appropriate specifications, depending upon user requirement. These broadly conform to the following parameters:

- Power required in simultaneous use and /or alternate use.

- Driven equipment details.

- Set to be used in simultaneous and (or) alternate operation.

WORKING OF PLURODRIVE

The prime mover (diesel engine) is connected to one end of the �PLURODRIVE�.

The driven equipment I [(DE I) pump] is connected directly on the opposite side of the PLURODRIVE.

Thus the DE I (pump) and prime mover (engine) have the same rpm. There is no belt connection between the prime mover and the DE I (pump).

An auxiliary output is provided on the PLURODRIVE to which a driven equipment II [(DE II) , say alternator is connected.

Rotary power from the prime mover can now be transmitted alternately or simultaneously as required by simple lever mechanism through the PLURODRIVE to the two driven equipments i.e. DE I and DEII, PLURODRIVE allows flexibility in speed and direction of rotation of DE II (alternator) vis-a-vis the engine (prime mover).

Generally, the entire assembly viz. the prime mover, then the PLURODRIVE, then the driven equipments are mounted and fixed on a single common frame.

The PLURODRIVE has mechanical lever(s), which can be easily moved by one operator within seconds.

Depending upon the requirement one can thus have either

- Option 1 : Pump (DE I) take power from engine when alternator is idle.

- Option 2 : Alternator (DE II) take power from engine when pump is idle.

- Option 3 : Run only prime mover keeping both equipments idle. Thus check prime mover performance, this is a distinct advantage offered by PLURODRIVE facilitating easy checking of the equipments, before and after any maintenance.

- Option 4 : Both pump (DE I) and alternator (DE II) take power from the engine simultaneously (possible with PLURODRIVE-sim alt).

The drive itself requires negligible maintenance and is designed and manufactured with the highest quality standard and in conformation with the latest design norms.

The standard range of PLURODRIVE is available from 20 hp upto 500 hp and has been subdivided into

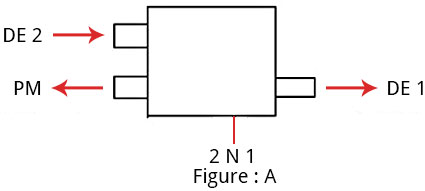

PLURODRIVE alt

Only alternate operation between any two driven equipments. So, the lever has positions II, N & I (as shown in A of the schematic below).

Figure A shows the most simple drive arrangement. Prime mover (PM) alternately powers driven equipment I (DE I) or driven equipment II (DEII).

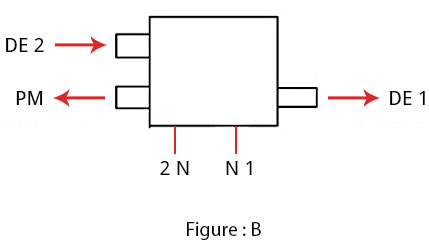

PLURODRIVE � sim alt

Both simultaneous and alternate operation between the two driven equipments. So, 2 levers have positions I & N and II & N respectively (as shown in B of the schematic below).

Prime mover (PM) can simultaneously or alternately power driven equipment I (DE I) and (or) driven equipment II (DE 1I) (shown in figure B).

For special applications We can provide PLURODRIVE for

- Running more than two driven equipments, simultaneously or alternately.

- Incorporating more than one prime mover into the system.

- Higher sizes can also be given, send detailed inquiry of your application.

Note

- Position of pump and alternator can be interchanged.

- Driven equipments such as welding alternator, compressor, cutter, conveyor, mixer, thresher, harvester, etc. can be incorporated into the system as required.

- In simultaneous operation prime mover power should be greater or equal to total demand of the operating driven equipments.

- Generally, direction of rotation of PLURODRIVE is clockwise when seen from driving end

CONCLUSION

So this is in short the concept, principle and working of this unique interface. It is obvious that this is most suitable for use at places where any two applications like water pump, electric power, welding, etc. are required to be used, which can be driven by a single prime mover. Common user areas can be petrol pumps stations, housing complexes, construction sites, factories, farms, hotels and many more, depending on requirements.